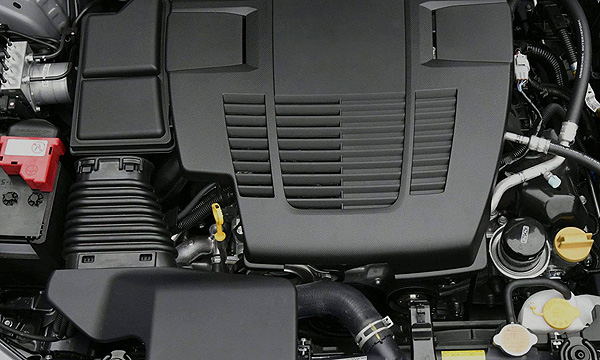

With the popularization of automobiles, people's requirements for the comfort, economy and safety of automobiles are constantly increasing. The types of electronic products on automobiles are also increasing. The wiring harness of automobiles is becoming more and more complicated, and the failure rate of wiring harnesses is correspondingly increased. This requires improving the reliability and durability of the wire harness. We have developed various solutions to meet these different requirements.

Since the introduction of all products into the RoHS standard at the end of 2004, the raw materials of each batch have been regularly submitted to the third-party authority SGS Testing Center for testing to ensure that the products delivered to the custom

Since the introduction of all products into the RoHS standard at the end of 2004, the raw materials of each batch have been regularly submitted to the third-party authority SGS Testing Center for testing to ensure that the products delivered to the custom

Since the introduction of all products into the RoHS standard at the end of 2004, the raw materials of each batch have been regularly submitted to the third-party authority SGS Testing Center for testing to ensure that the products delivered to the custom

| Exterior | Cylindrical, uniform particles, consistent coloration |

| Dispersibility | Colorless dots, spots, stripes melting |

|

Proportion |

1.3-1.45g/cm3 |

|

Hardness |

60A-98A |

|

Tensile Strength |

1000-4000PSI |

|

Elongation |

100%-300% |

|

Melting Temperature |

150-200℃ |

|

Environmental Compliance |

RoHS/REACH/NP/TCO 10.0 Compliant |